Design Process

Define a Problem

This project aims to have a machine repeatedly play one note on a piano with minimal effort. The mechanical advantage must be greater than one, so less effort than resistance must be used. We had to use at least three simple machines in our design. Here I explain our design process while creating this machine.

Generate Concepts

Brianstorming List:

* Machine that plays a note on a piano

* Machine that lifts a heavy book

* Machine that shoots a ping pong ball

Decision Matrix:

| Machine | Creativity | Simplicity to add 3 simple machines | Total |

| Playing Piano | 1 | 2.5 | 3.5 |

| Lifting a Book | 3 | 1 | 4 |

| Shooting a Ping Pong Ball | 3 | 3 | 6 |

Key: Scored 1 to 3, 1 is best and 3 is worst

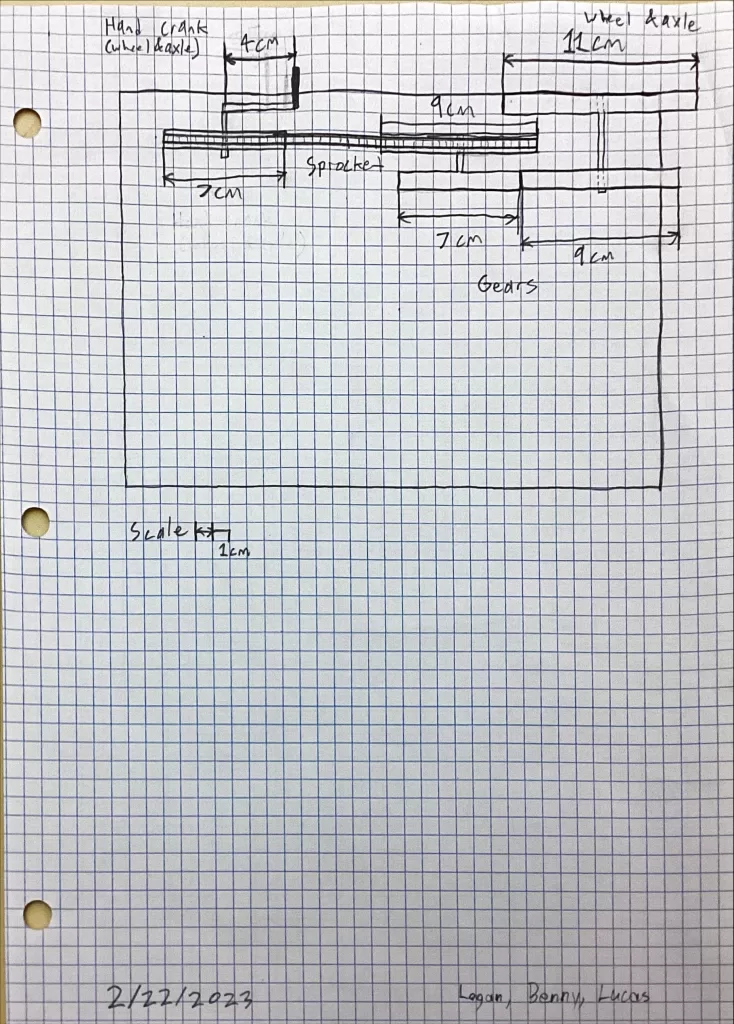

Develop a Solution

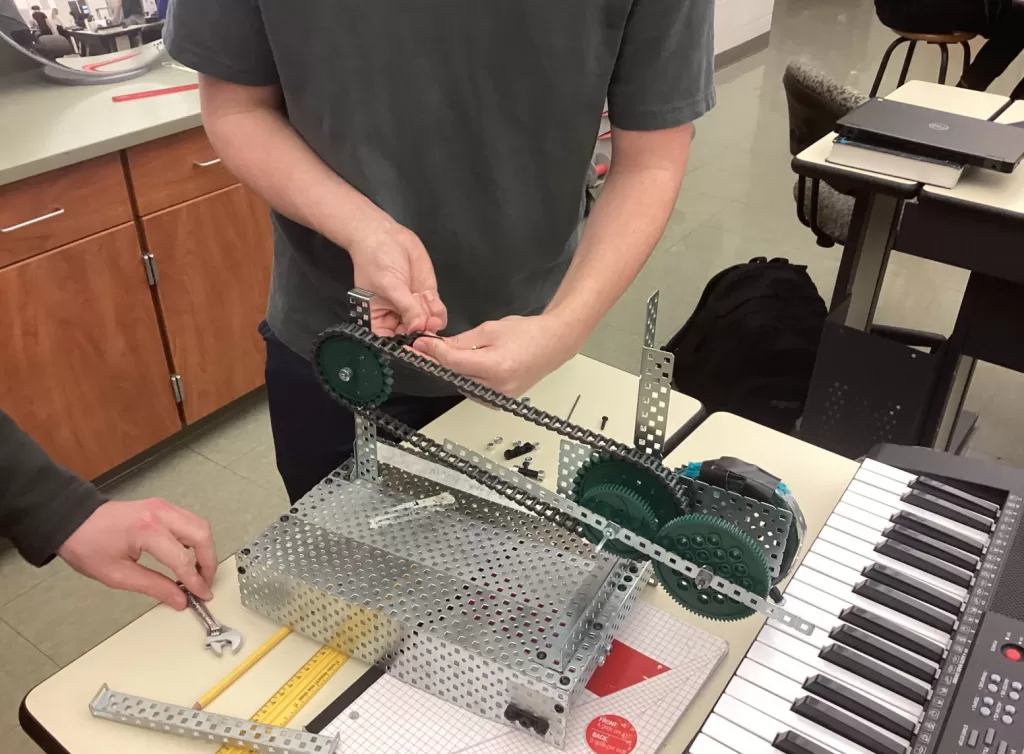

Construct and Test Prototype

Our machine meets multiple constraints:

* We only have a single human input.

* We used 4 simple machines in our design. The hand crank represents a wheel and axle.

We use sprockets to transfer force. To gain a higher mechanical advantage, we used gears, and another wheel and axle is used to play

the piano and gain an even higher mechanical advantage.

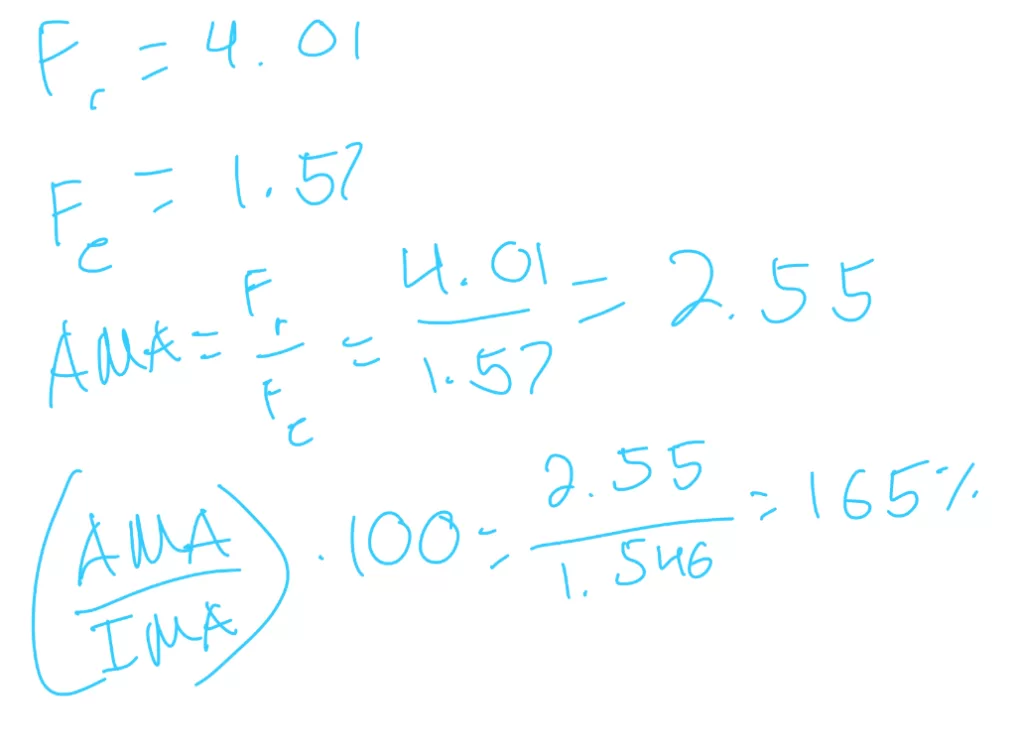

* Our overall ideal mechanical advantage is 1.546 , which is greater than 1.

Our actual mechanical advantage is 2.55 , which gives us an efficiency of 165%.

* After fixing a few problems, our machine now works flawlessly and consistently.

* We minimized friction, so very little efficiency is lost.

Evaluate Solution

We used VEX components to create our complex machines.

VEX components are not frictionless, and the axles are square, so a lot of friction can occur.

Bearings are not available, so we just had to leave everything a bit loose to avoid excess friction.

We used movable axles to minimize friction and adjusted the chain on the sprockets to work perfectly.

The chain could not have too many links, or it would slip, and it could not have to little links, or it would cause more friction.

Our test data is below:

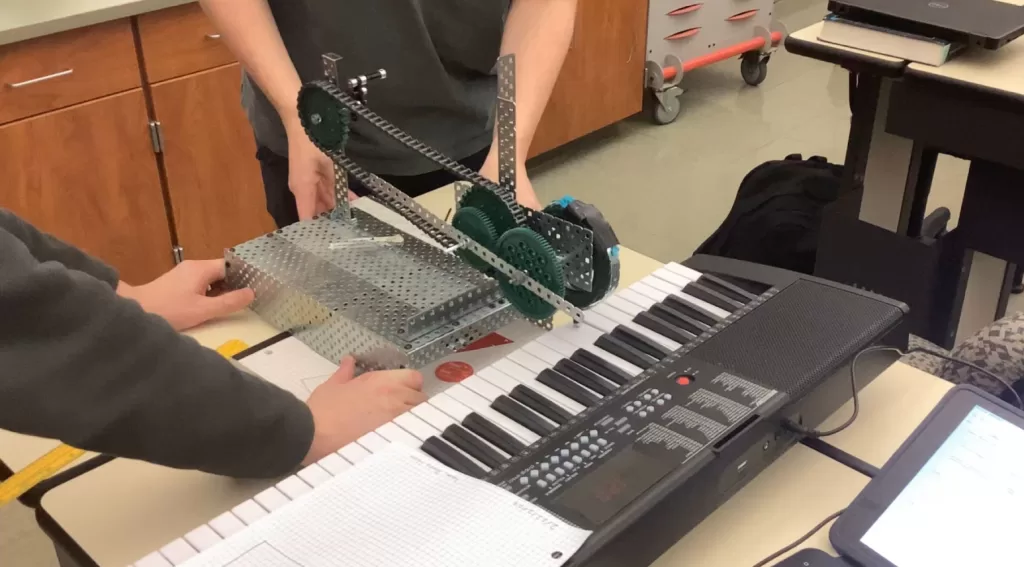

We made a few mistakes along the way such as making the hand crank too short, having too many links in the sprocket,

using axles that were too short, and having the machine be too low. To solve these problems, we extended the hand crank,

took links out of the sprocket chain, started using longer axles, and mounted the machine higher up so it struck the keys correctly.

Throughout the design process, we learned how to use time efficiently, how to divide tasks among our team, how to minimize friction.

Oh, and of course how to make a simple piano playing machine!

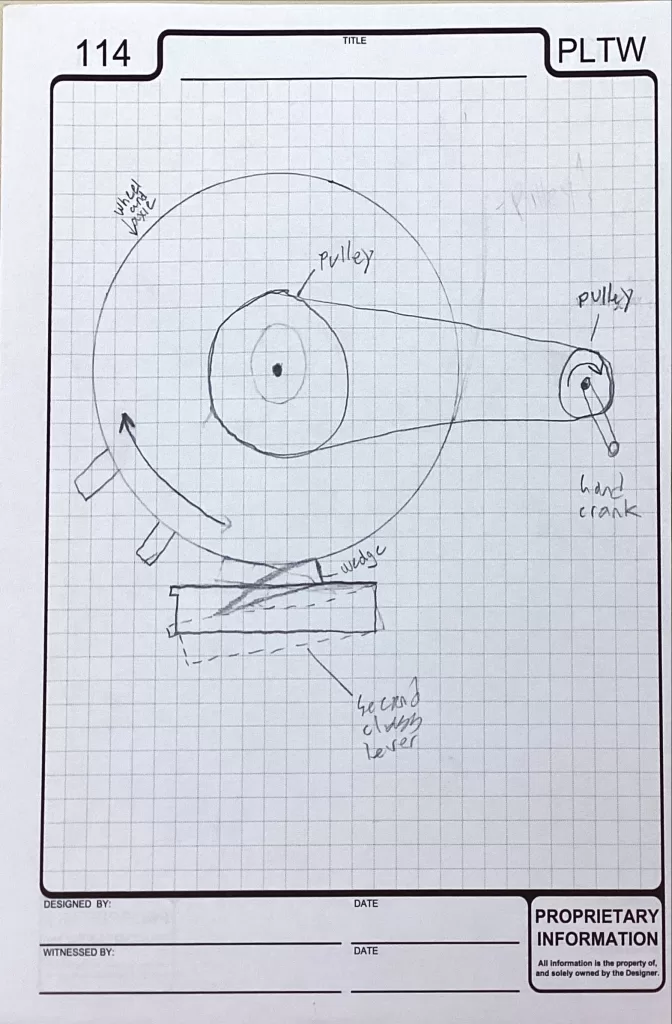

We had to modify the design multiple times. In our original sketch we thought of using pulleys,

but decided to use a sprocket and gears to prevent slipping. Our sprocket had too many chain links, so we took a few out.

We also had to use longer axles to accommodate unforeseen modifications.

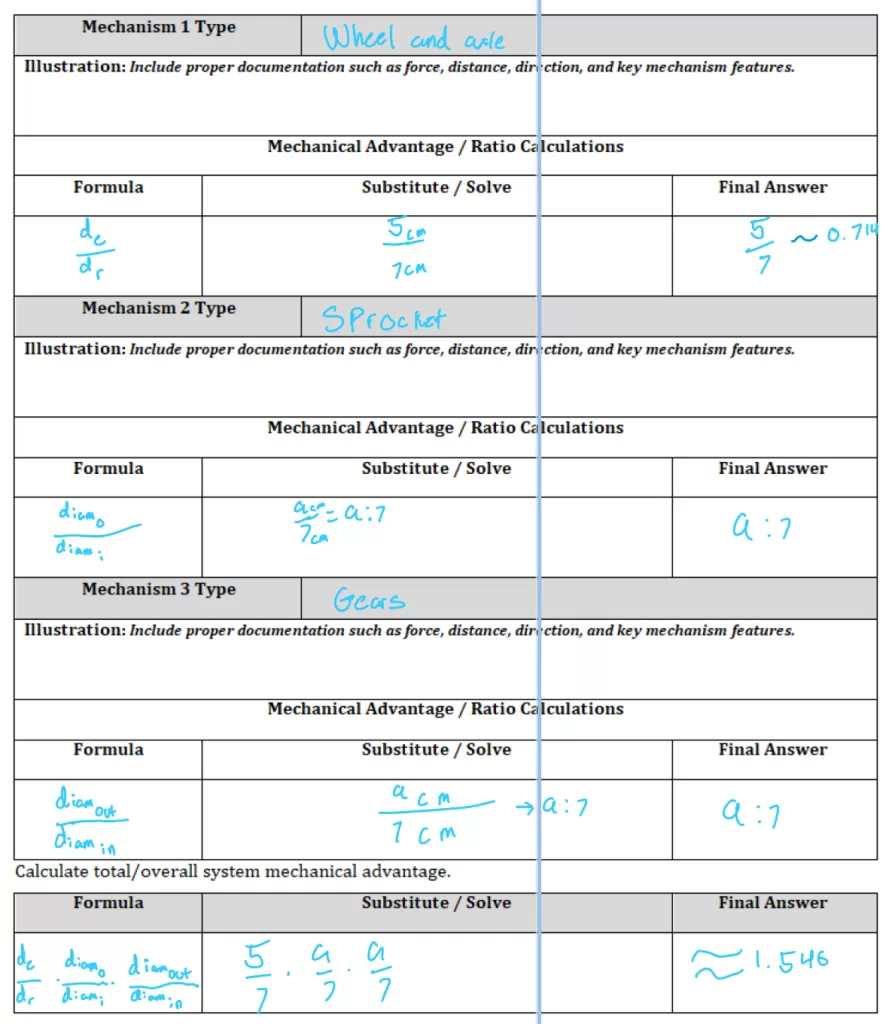

Our Ideal Mechanical Advantage (IMA) used measurements from the diameters of the gears, wheels and axles, and sprockets.

Our IMA was 1.546 while our AMA was 2.55 , meaning our efficiency was 165%. This was surprising, as we expected an efficiency less than 100,

but we could have measured the AMA incorrectly with the force sensor. Another possibility for this efficiency is that we rounded our

diameter measurements to the nearest half centimeter, so our calculations could be inaccurate. When we tested the AMA with the force sensor,

we could have pressed the piano key too hard, which would give us inaccurate measurements.

Present Solution

Conclusion

It was easiest to determine the gear ratio of the sprocket, since it was easy to access and take measurements.

In contrast, it was difficult to measure the mechanical advantage of the gears since they cause a lot of friction and were hard to access.

We had reinforced their connection from both sides so they meshed properly, but that also meant that we could not find the diameter or

radius easily.

To further improve the efficiency of the compound machine, we could lubricate the axles, increase the radius of the hand crank,

or use gear ratios with a higher mechanical advantage.

It would also be fun to add more wheels and axles on the end of the design with a shared axle to play different notes on the piano.

Due to time constraints, we were only able to add one wheel to play a single note. To add more wheels, a longer axle would be required.