Design Process

Define a Problem

Generate Concepts

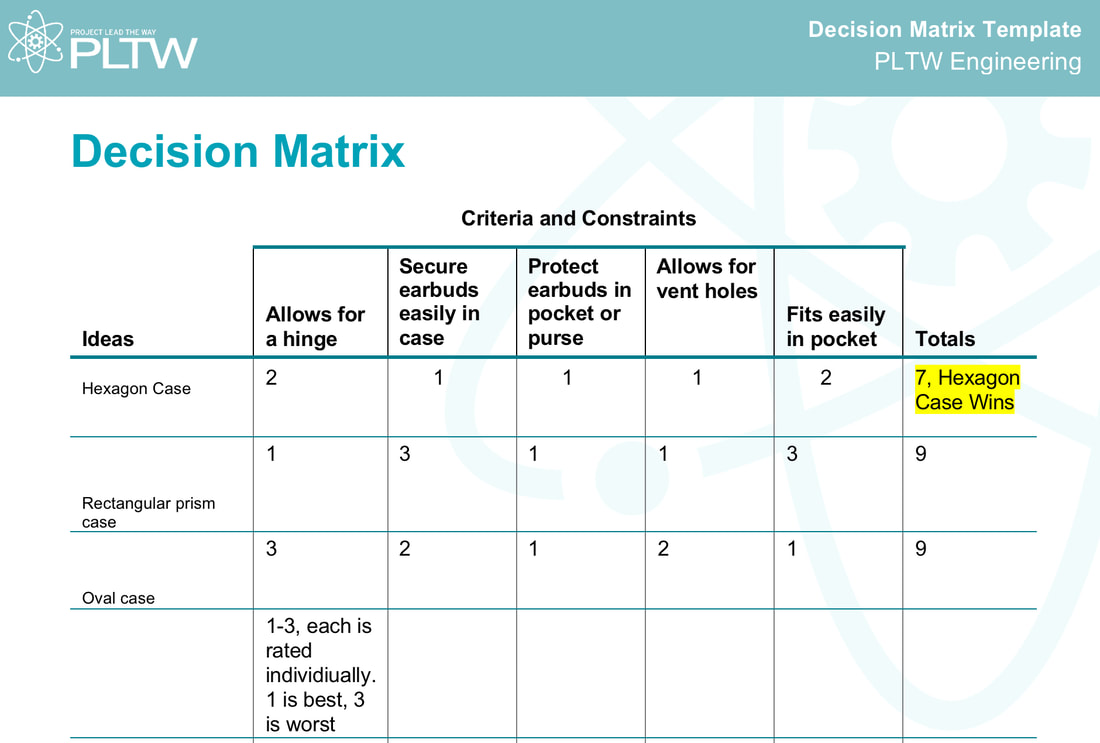

Making a case machine is the best choice since it is small, easy to reset and setup, profitable, and very fun to play. This can be seen in the decision matrix

Develop a Solution

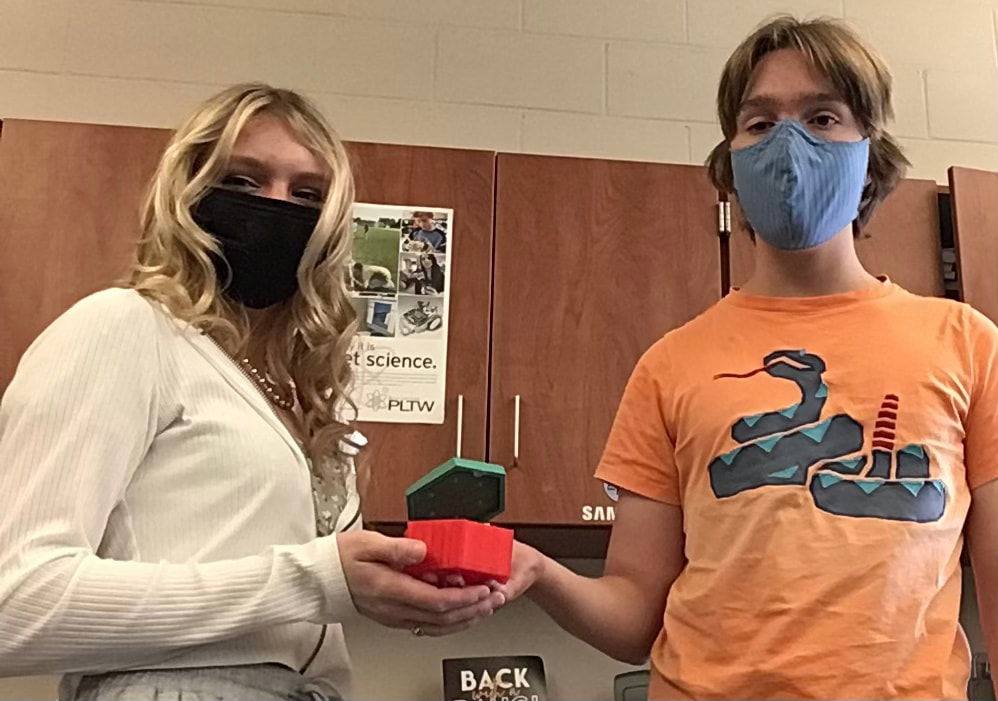

Construct and Test Prototype

It took 2 hours to print the lid. It takes less than 7 seconds to put the earbuds into the case since you just wind it around the center column. The hinge did not fit together perfectly, I needed to cut it apart and super glue it back together afterwords. This could be easily fixed by using a smaller hinge or using a design where the parts revolve around a pin that is slotted into the design.

Evaluate Solution

Why does your preliminary design merit further development? That is, why is this solution worth pursuing?

This solution is worthwhile since it can add a stylish addition to the earbuds without a change in the design of the earbuds.

It accomplishes the task of protecting the earbuds, and is easy to produce.

It is an effective solution to making sure the wires do not detach from the earbuds.

What are your suggested next steps for design iteration that would improve the design?

Using a different hinge design would make the construction much easier and more durable.

Having a hole and pin system where both the top and bottom have a thru hole and a pin that slides through the top and bottom

would effectively achieve this task.

Could you add criteria or constraints to the design brief that would improve your ability to more

effectively compare potential solutions?

It would be important to add maximum dimensions such as height to ensure that the case fits comfortably in the user's pocket.

Along with this, the magnet hole diameter would need to be accurately specified in order to ensure that the magnet fits well.

The cost would need to be calculated in order to profit. And a more stylish design would draw a greater amount of customers to buy the case.

Present Solution

Different types of models used, along with their advantages, disadvantages, and their purpose for use.

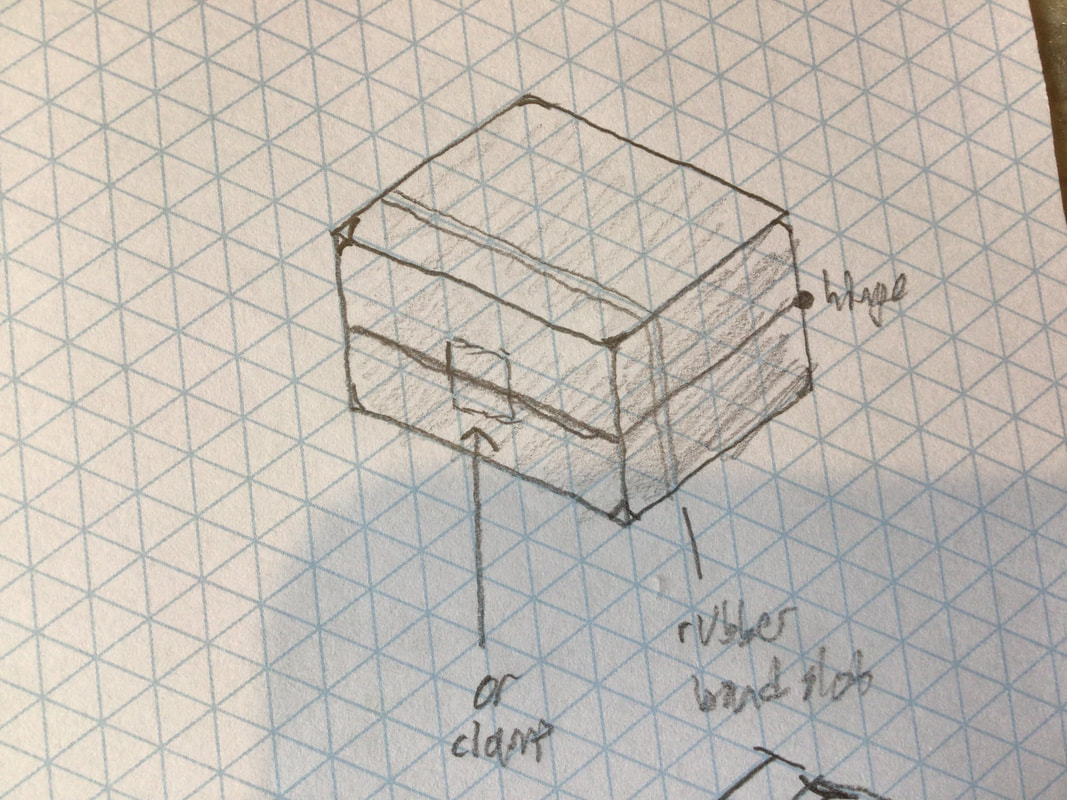

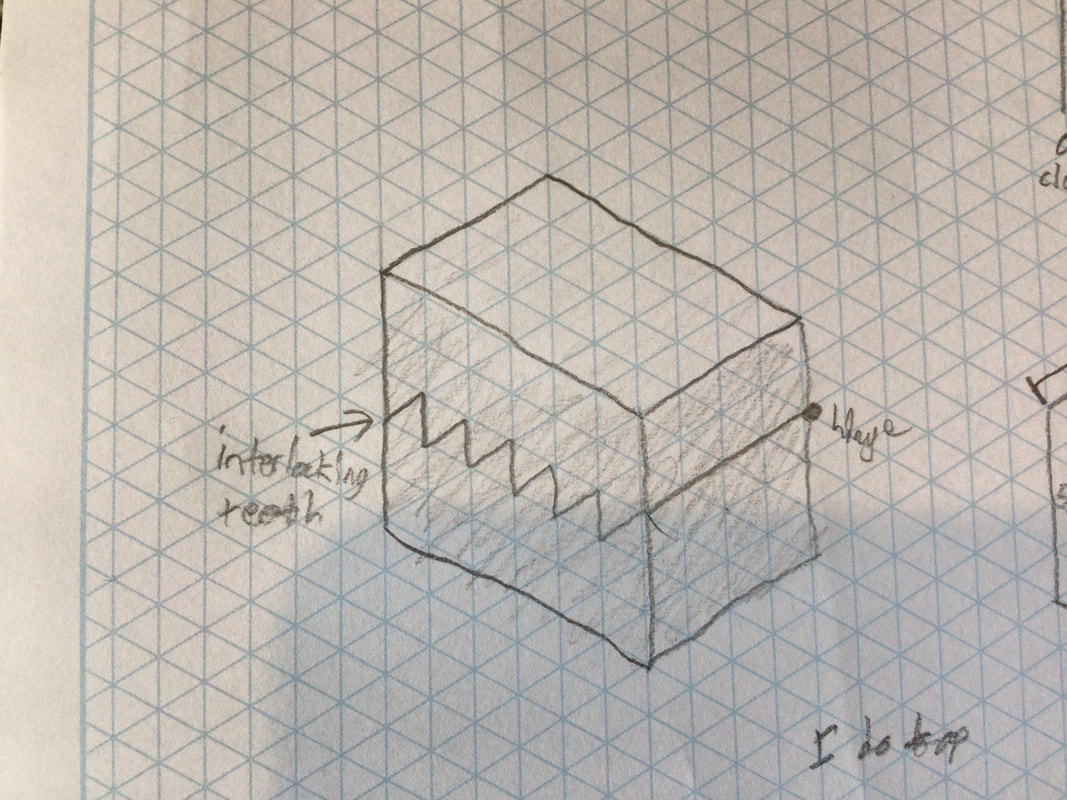

First, I made a rough sketch. This served as just a quick way to get record some ideas.

The sketches were very limited since they were not dimensioned and could not be viewed from all sides.

It helped me brainstorm some ideas and made me think about features of the design.

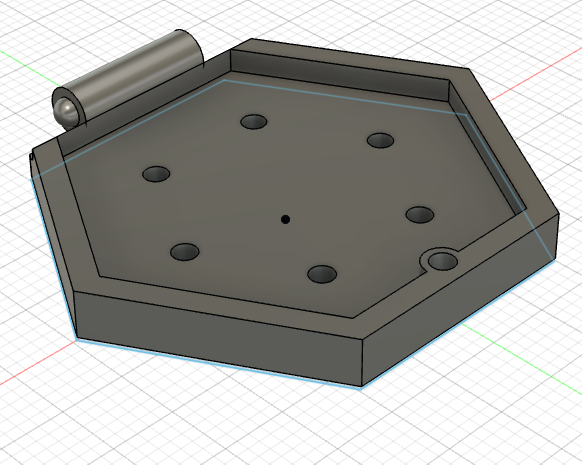

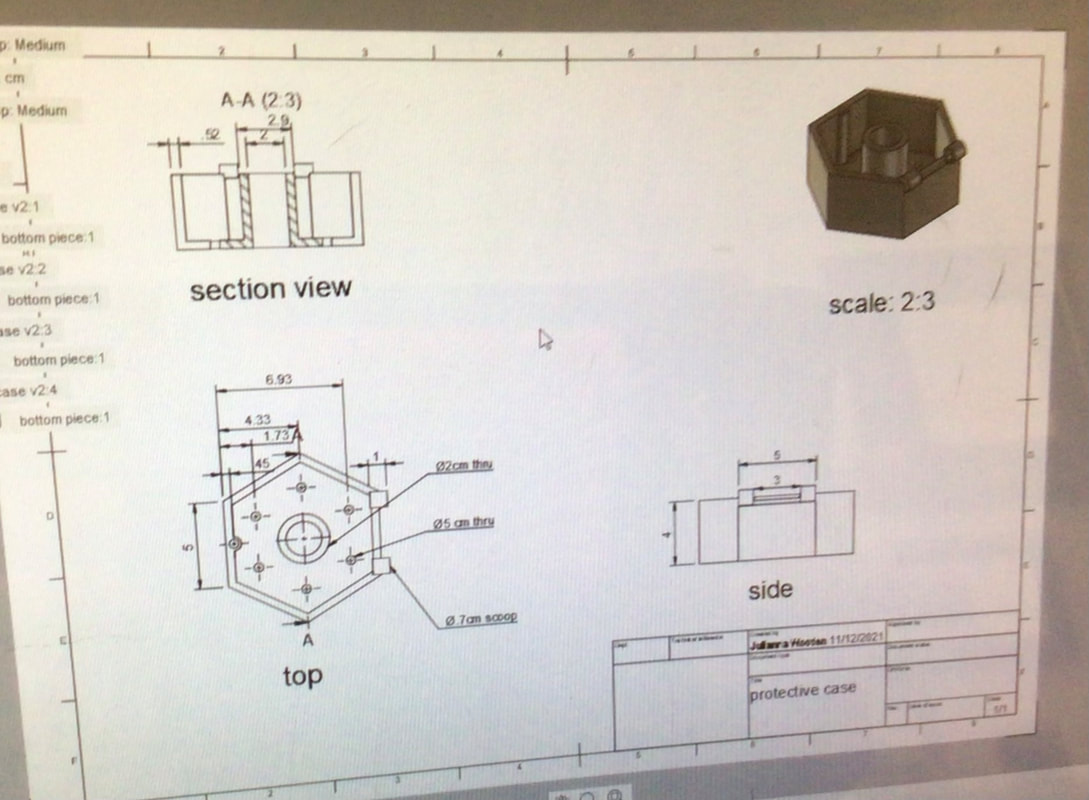

The second model that I created was a 3D CAD model, made using Autodesk Fusion 360.

This model was very precise and could be viewed in a 3D environment.

The dimensions were not easily visible unless you used the Measure tool or looked at the sketch in Fusion 360.

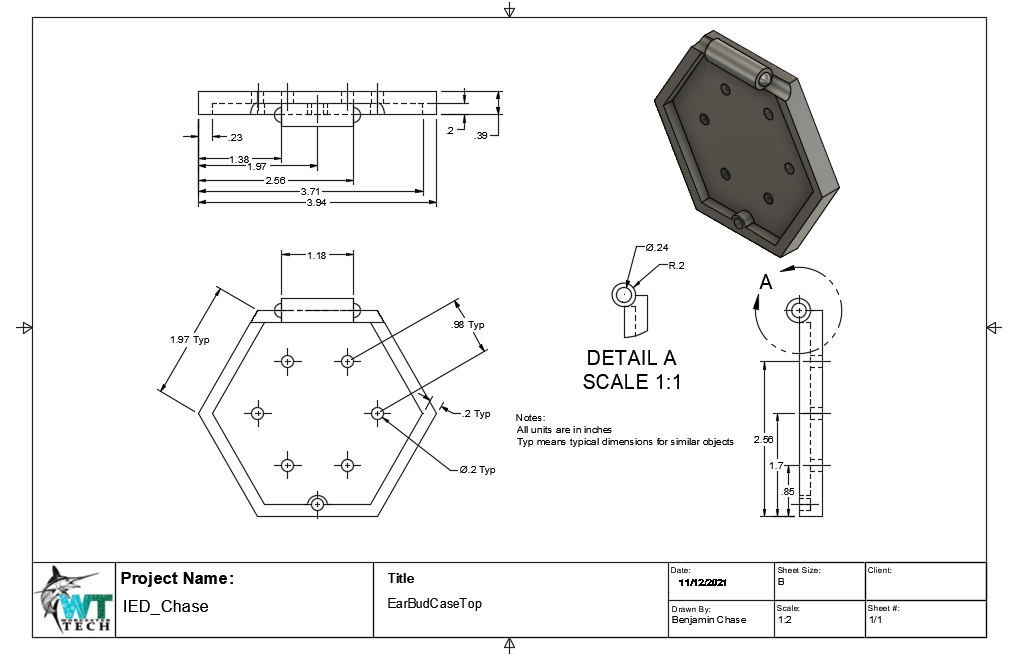

After that, I created a drawing in Fusion 360. This model accomplished what the previous model had not.

It had easily readable extremely precise dimensions.

It could be modified by changing the previous 3D model which automatically altered the drawing.

But the model could not be viewed in 3D, and would be harder for people without an engineering background to understand than the 3D model.

It helped by adding precise dimensions to the design.

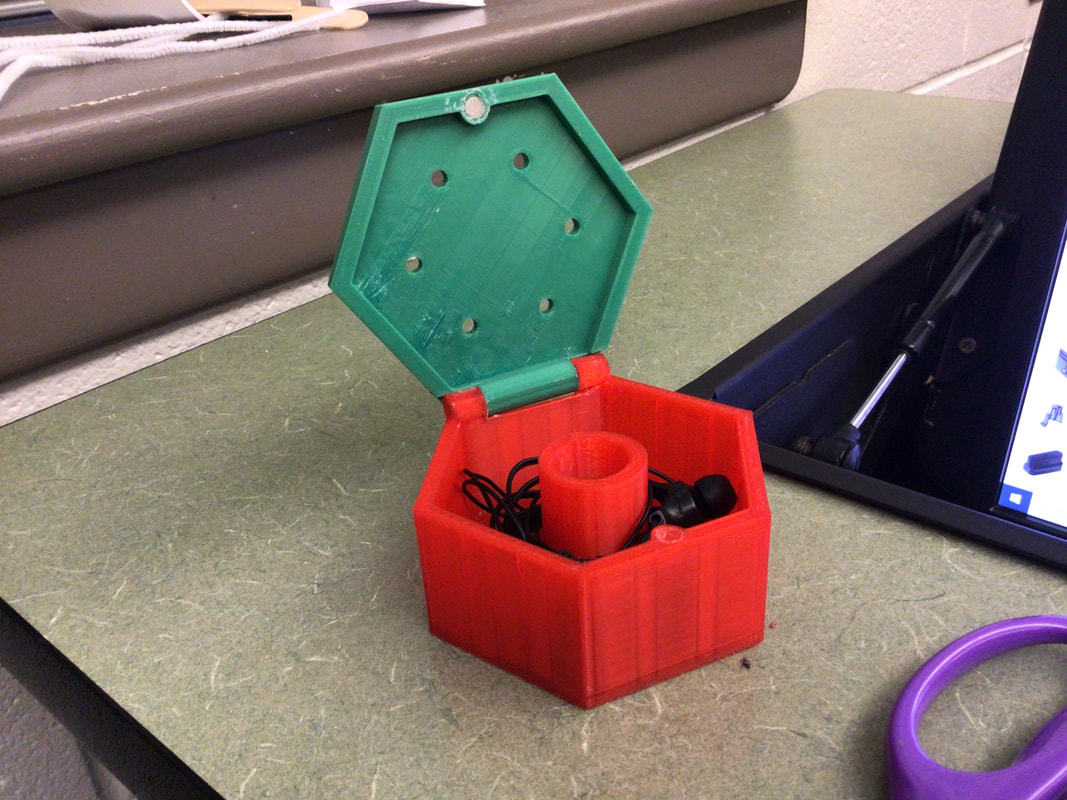

The final model was a prototype model. It was 3D printed. This model had multiple advantages as well as disadvantages.

It was hard to make it work, the pieces did not fit well together due to the hinge.

But it demonstrated a real case and made it easy to spot changes which could be applied in the 3D model.

It was much harder to modify this model than any previous models.

Review of goals:

The hinge:

The hinge did not work perfectly. It did not fit together, so I had to cut it apart and glue it back together.

This could be improved using a pin that would go through both the top and bottom parts.

Easy and quick insertion:

The earbuds could easily be wound around the center pillar in less than seven seconds, and the magnets made it easy to close the case.

The case will protect the earbuds and will not break:

The case would protect the earbuds, but the hinge was weak and could easily break.

Again, this could be easily fixed by adding a simple pin which would go through the entire hinge part instead of the half spheres.

Allows for vent holes:

The vent holes were perfect, and no parts of the earbuds could go through them. They integrated very well with the case.

There is one concern I have though: Occam's Law states that you should remove any unimportant features for simplicity since

it will remove possible issues. I see no need for vent holes, the earbuds would not overheat as they are not plugged in.

And for cleanliness, things from inside your pocket such as lint could potentially get inside the case making it dirtier.

My opinion is that the vent holes are not needed.

How previous experiences and skills helped me with this project:

It helped knowing how to use Fusion 360 from Intro to Engineering. Learning about dimensioning in Intro to Engineering was also important.

And the design process was very useful when creating this project and the design.

Teamwork was important, all the dimensions needed to work together.

And 3D printing skills are always useful in an engineering project to maximize the prototype print quality.